RESEARCH & DEVELOPMENT

Studies at the Defender-Plus R&D laboratory in Hartville, Ohio allow us to isolate and control almost every variable in corrosion testing. We are still unlocking the tremendous potential of our Electromagnetic Induction Corrosion Control Technology (EICCT) and are committed to advancing both the pure science and its application to the automotive industry.

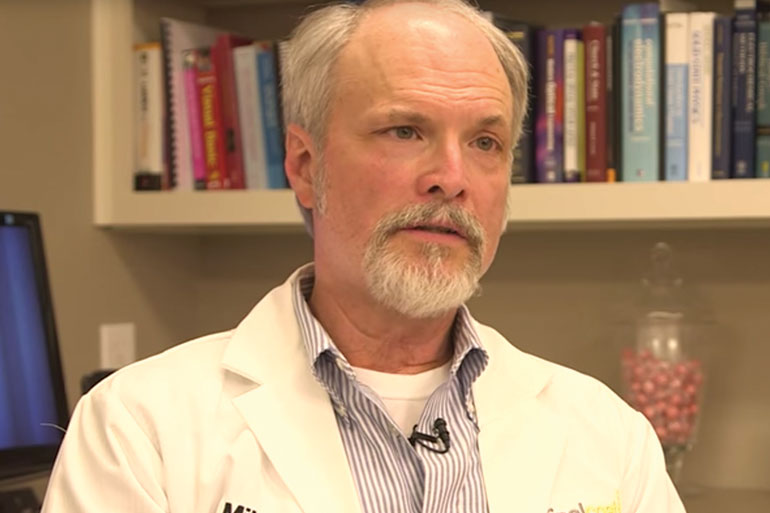

We employ three full-time scientists to lead our corrosion research. Dr. Michael Lewis invented the technology in 1997 and was hired by Defender-Plus in 2004. Dr. Jason McLafferty joined in 2009. Both scientists, plus two full-time lab assistants, work under the guidance of a world-class corrosion scientist, Dr. Digby Macdonald.

Lab Testing

CCT Laboratories

- Independent laboratory

- Located in Dublin, Ohio

- Previously retained by Federal Trade Commission

- Employs 14 Doctorate level scientists and 35 engineers

Test conducted: 2002-03 for the Canadian government’s Competition Bureau

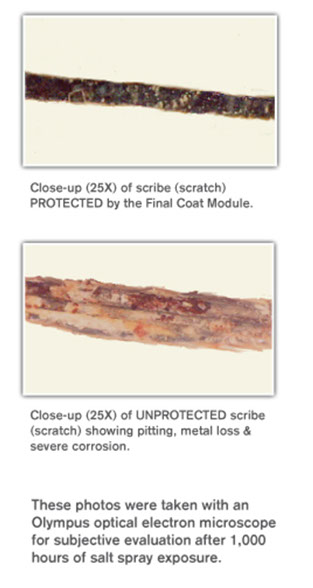

Type of Test: Salt Spray over the scribed area only. Test was done to show the efficiency of the Defender-Plus Electronic Corrosion Module over a surface in the absence of an electrolyte (moisture) film and it’s ability to reduce the rate of corrosion. Test Panel Size: 4 feet x 3 feet

Test Results: “The corrosion rate is reduced by 99.7% by the Module on the Test Panel compared with the Control Panel. Even if the difference in the corrosion potential is reduced to -0.100V, the ratio (CR) test/ (CR) control = 0.0204 and hence the corrosion ratio is reduced by 98%. To put these numbers in perspective, imagine that a system (automobile) fails by corrosion without the Module in a time of 1 year. If the Module is attached, the failure time would be 343 years if the potential is displaced by 150 mV in the negative direction, and 49 years if the potential was displaced by only 100mV. Such results are particularly significant when one considers that the average life of a vehicle is in the order of 10 years. Accordingly, these calculations demonstrate that the reduction in corrosion rate is substantial and that the Module is an effective corrosion control device”.

Note: The corrosion potentials measured at the scribes on both panels were approximately the same until exposure times exceeded 60 hours. The potentials then diverged, with that for the test panel eventually becoming more negative than that for the control panel by about 150mV, indicating that an induction time exists for the Corrosion Module to exert

Download PDF

ULC Laboratories

Salt Spray Test: Performed to ASTM D1654-92 Standards (Test Method for Evaluation of Painted or Coated Underwriters’ Laboratories of Canada

- Independent laboratory located in Toronto

- In business of testing for over 80 years

- Conducted in accordance with ASTM Standard D1654

Test conducted: 2001

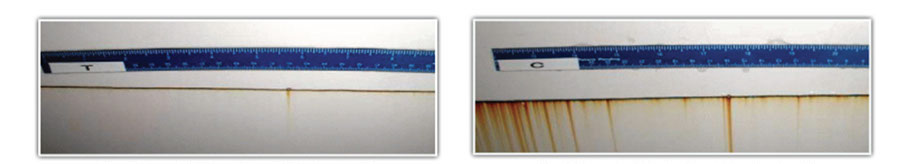

Type of Test: Salt Spray Test performed to ASTM D1654-92 Standards (Test Method for Evaluation of Painted or Coated Specimens Subject to Corrosive Environments) Test Panel Size: Four panels each measuring 4 feet by 4 feet were grounded together giving a test surface area equal to 128 square feet. All panels were scribed.

Single Panel Test: Two painted galvanized automotive sheet metal panels measuring 4 feet x 4 feet Panels prepared in accordance with DCX specifications Scribed to expose bare metal One panel connected to Module Placed in heated salt spray chamber for 1000 hours (40 days)

Conclusion on Single Panel Test: Unprotected panel “showed corrosion and rust damage” Panel connected to Module “showed no corrosion or rust”

Multiple Panel Test: Four panels each measuring 4 feet x 4 feet Panels connected by conductive wire Each panel scribed to bare metal One panel connected to Module

Conclusion on Multiple Panel Test: “all panels showed no corrosion or rust” Compared with unprotected panel that “showed corrosion and rust damage”

Smithers' Scientific Services Inc.

- Independent Laboratory located in Akron, Ohio

- Testing conducted in 1997 on BodyGard module (rebranded Final Coat in 2004)

Type of Test: Humidity Test

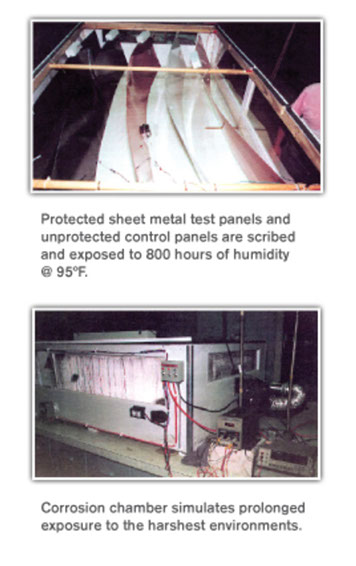

Test Panel Size: 2 sections (7 feet x 15 inches) connected by grounding strap

Test Results: "substantially reduced the corrosion rate".

Test Methodology Test conformed with ASTM Standard D1654 Four separate automotive sheet metal panels, each measuring 7 feet x 15 inches Each panel scribed to bare metal One panel connected, other three not connected 35 days (800 hours) of exposure in corrosion chamber

Conclusion “test panels…showed a marked degree of severe corrosion and rusting” “Scribes protected by BodyGard system (rebranded Final Coat) were nearly corrosion free” “The BodyGard system appeared to afford substantially more corrosion reduction than that of the factory panels tested” Test repeated two more times with consistent results

Since 1978, we've been dedicated to providing help for people with Alzheimer's disease and other dementias and their caregivers. That help comes in many ways.

Ohio State Electro Science Laboratory

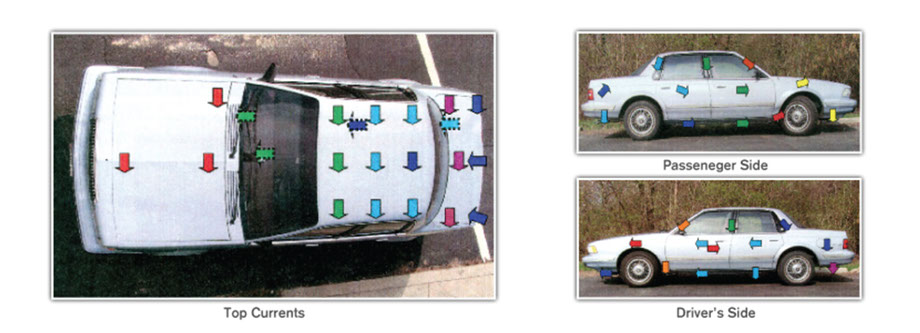

- Question arose in Canadian Competition Bureau hearing as to whether the induced current is uniformly distributed across the vehicle surface.

- This issue was studied by Ohio State University’s Electrosciences Laboratory on an instrumented vehicle.

- Current was found to be uniformly distributed across entire surface of vehicle.

Type of Test: Humidity Test

Test Panel Size: 2 sections (7 feet x 15 inches) connected by grounding strap Test Results: "substantially reduced the corrosion rate".

Test Methodology Test conformed with ASTM Standard D1654 Four separate automotive sheet metal panels, each measuring 7 feet x 15 inches Each panel scribed to bare metal One panel connected, other three not connected 35 days (800 hours) of exposure in corrosion chamber

Conclusion “test panels…showed a marked degree of severe corrosion and rusting” “Scribes protected by BodyGard system were nearly corrosion free” “The BodyGard system appeared to afford substantially more corrosion reduction than that of the factory panels tested” Test repeated two more times with consistent results

Download PDF

Elite Electronic Engineering Inc.

- Independent laboratory located near Chicago, Illinois

Type of Test: Humidity Test

Test Panel Size: 2 sections (7 feet x 15 inches) connected by grounding strap

Test Results: "substantially reduced the corrosion rate".

Test Methodology: Test conformed with ASTM Standard D1654 Four separate automotive sheet metal panels, each measuring 7 feet x 15 inches Each panel scribed to bare metal One panel connected, other three not connected 35 days (800 hours) of exposure in corrosion chamber

Conclusion: “test panels…showed a marked degree of severe corrosion and rusting” “Scribes protected by BodyGard system were nearly corrosion free” “The BodyGard system appeared to afford substantially more corrosion reduction than that of the factory panels tested” Test repeated two more times with consistent results

DR. MICHAEL E. LEWIS, PHD

INVENTOR/PHYSICIST

is the inventor of EICCT and the leader of the Defender-Plus R&D Department, with a PhD in Physics from Kent State University in 1987. Dr. Lewis has twenty-two patents and invented a new electronic corrosion reduction method in 1997. He has designed various environmental chambers and a Raman spectrometer for surface chemical analysis. While with Cisco Systems, he led a communications systems engineering group where he directed the architectural design of digital signal processing integrated circuits for digital communications and was responsible for the design and direction of several large scale communications computer simulations. As a faculty member and consultant, Dr. Lewis has directed a multidisciplinary materials science research effort to study the relationship between the molecular structure and the third-order optical nonlinearity of metal organic polymers and monomers and has worked extensively in the fields of laser physics, optoelectronics, optical modulation and liquid crystal physics.

DR. JASON MCLAFFERTY, PHD

SCIENTIST/ELECTROCHEMIST

has a Bachelor of Science degree in Chemistry from Penn State Erie, the Behrend College. He then worked at Alcoa’s Research Laboratories and became interested in electrochemistry. Based on this interest, he decided to do his doctoral dissertation research with Dr. Digby Macdonald in the Department of Materials Science and Engineering at Pennsylvania State University. He co-wrote two invention disclosures on Regeneration of Sodium Borohydride. Jason graduated with his PhD in Materials Science and Engineering from Pennsylvania State University with dissertation research in electrochemistry. In 2009, he joined Dr. Michael Lewis at our research facility to explore the electrochemical side of our patented technology.

DR. ENRIQUE MAYA-VISUET

SCIENTIST/CORROSION ENGINEER

holds a doctorate degree in Chemical Engineering and Materials Science, specializing in Electrochemistry from The University of Akron. He also holds Master and Bachelor level degrees in Corrosion/Metallurgy from the National Autonomous University of Mexico. From 2011 to 2015, he worked as a PhD Research Assistant at The University of Akron. In that role, he led and conducted research in the development of coating systems and material selection for corrosive environments, employing mathematical simulations. Selected project experience includes materials selection for Cargill Inc., electrochemical coating evaluation for PPG Industries, and damage evolution characterization for Tesla NanoCoatings Inc.

Dr. Maya-Visuet’s research and publications to date have been focused on the effects of pigmentation on polyurethane/polysiloxane hybrid coatings, electrochemical characterization of select stainless steel alloys in the presence of chloride and bromide solutions, and the effect of chloride ions on the electrochemical performance of stainless steel alloys in concrete and simulated concrete-pore solutions. Dr. Maya-Visuet has also presented several papers for both NACE International and Electrochemical Society conferences. He is a member of NACE International, ASM International, and The Electrochemical Society.

DR. DIGBY MACDONALD, PHD

SCIENTIST/CORROSION CONSULTANT

is one of the world’s leading corrosion scientists and Professor in Residence in the Departments of Nuclear Engineering and Materials Science and Engineering at University of California at Berkeley. From 2003 to 2012, he was a Distinguished Professor of Materials Science and Engineering Director for the Center for Electrochemical Science and Technology at Penn State University. Dr. Macdonald has published over 900 papers in scientific journals, books and conference proceedings. He is the author of a book entitled “Transient Techniques in Electrochemistry” and holds 9 patents. In 2003, Dr. Macdonald received the highest award in the field of corrosion science and engineering – the U.R. Evans Award from the Institute of Corrosion in the United Kingdom. In 2011, he was nominated for the Nobel Prize in Chemistry. Dr. Macdonald holds a B.Sc. (1965) and M.Sc. (1966) in Chemistry, University of Auckland (New Zealand) and Ph.D. in Chemistry (1969), University of Calgary (Canada).

Q&A With Michael Lewis

Interview with the inventor of the electromagnetic indusction corrosion control technology (EICCT) used in the Defender-Plus modules

Watch Video

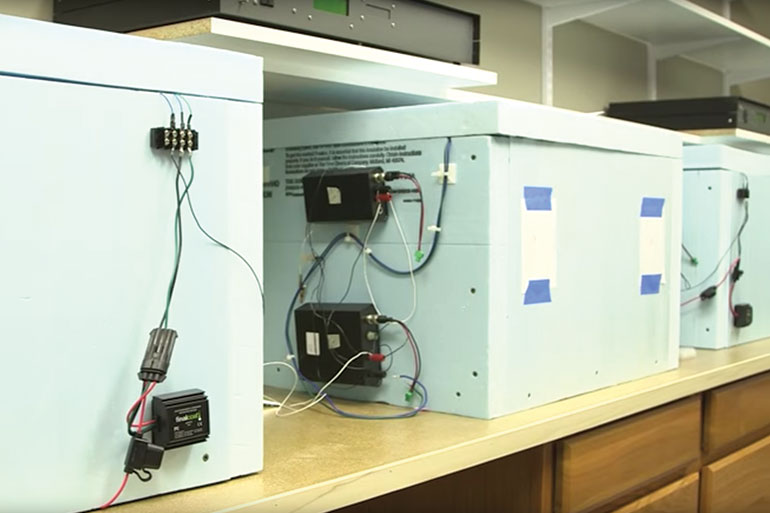

Q-Fog Lab

Q-Fog test chambers are used in the corrosion research industry to simulate conditions that metals are exposed to in the natural environment

Watch Video

Static Electrolyte Lab

Testing the exposure to a static volume of electrolyte on galvanized sheet metal

Potentiostat Experiments

Cause and effect experiments to confirm different hypotheses on corrosion and zinc passivation

Watch Video

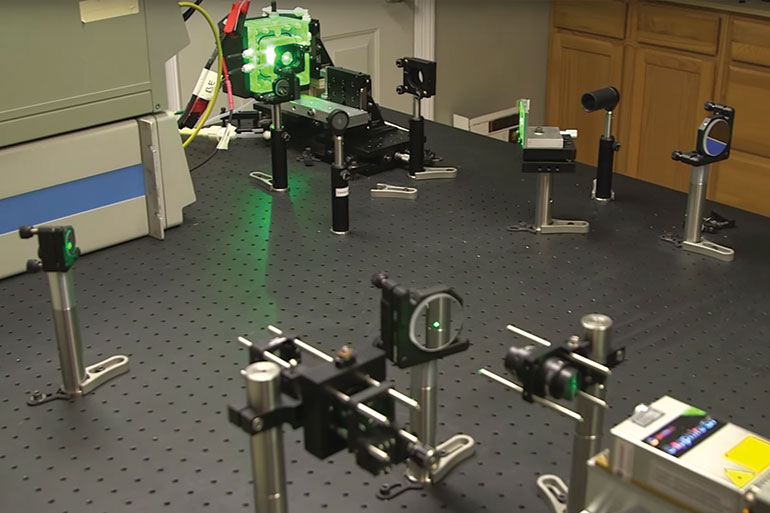

Raman Spectroscopy Lab

Allows for the study of surface corrosion products on samples immersed in an electrolyte

Watch Video© 2017. Defender-Plus. All Rights Reserved.